Small update coming at y’all- and while it’s small, the process behind this was large.

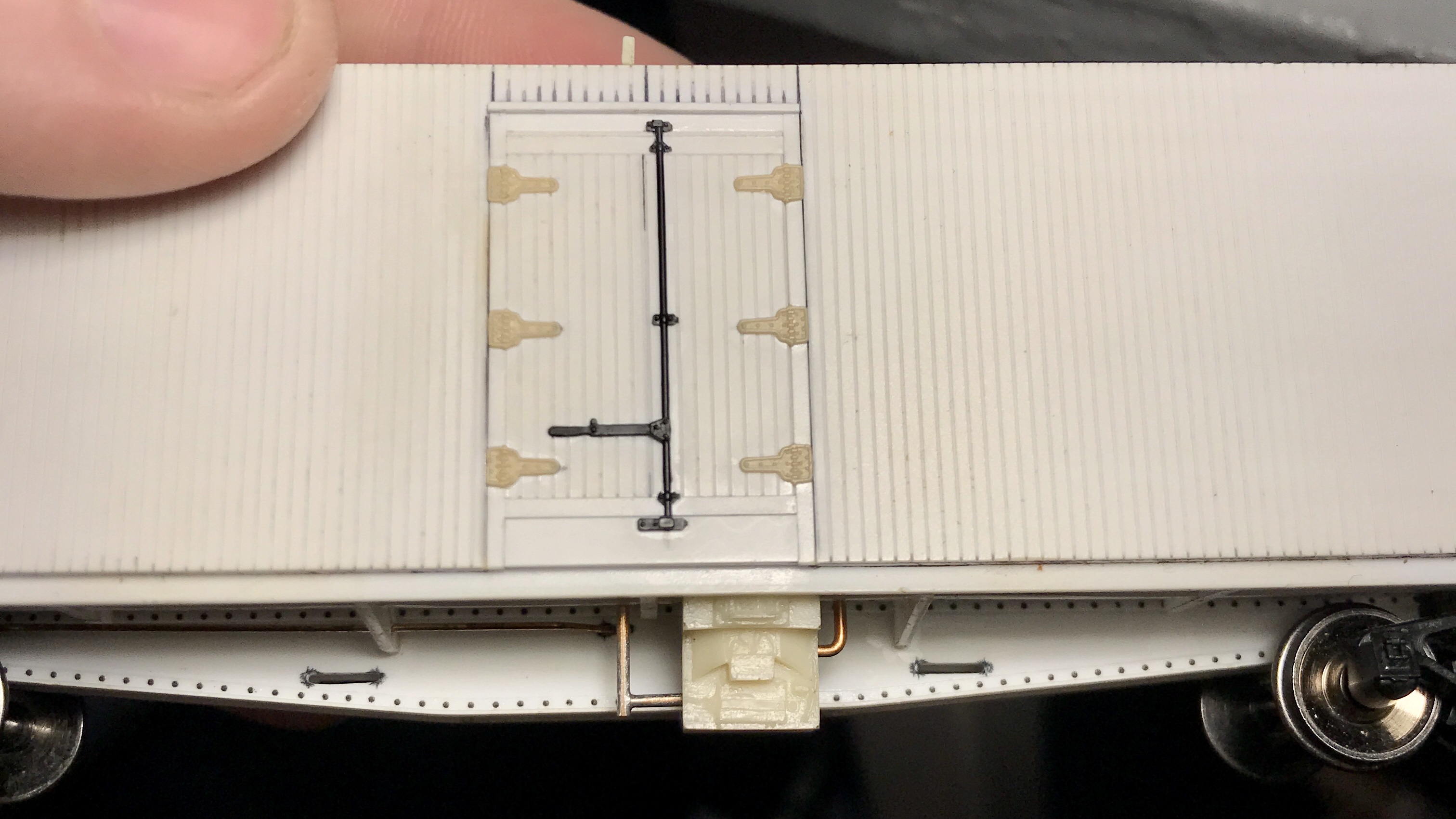

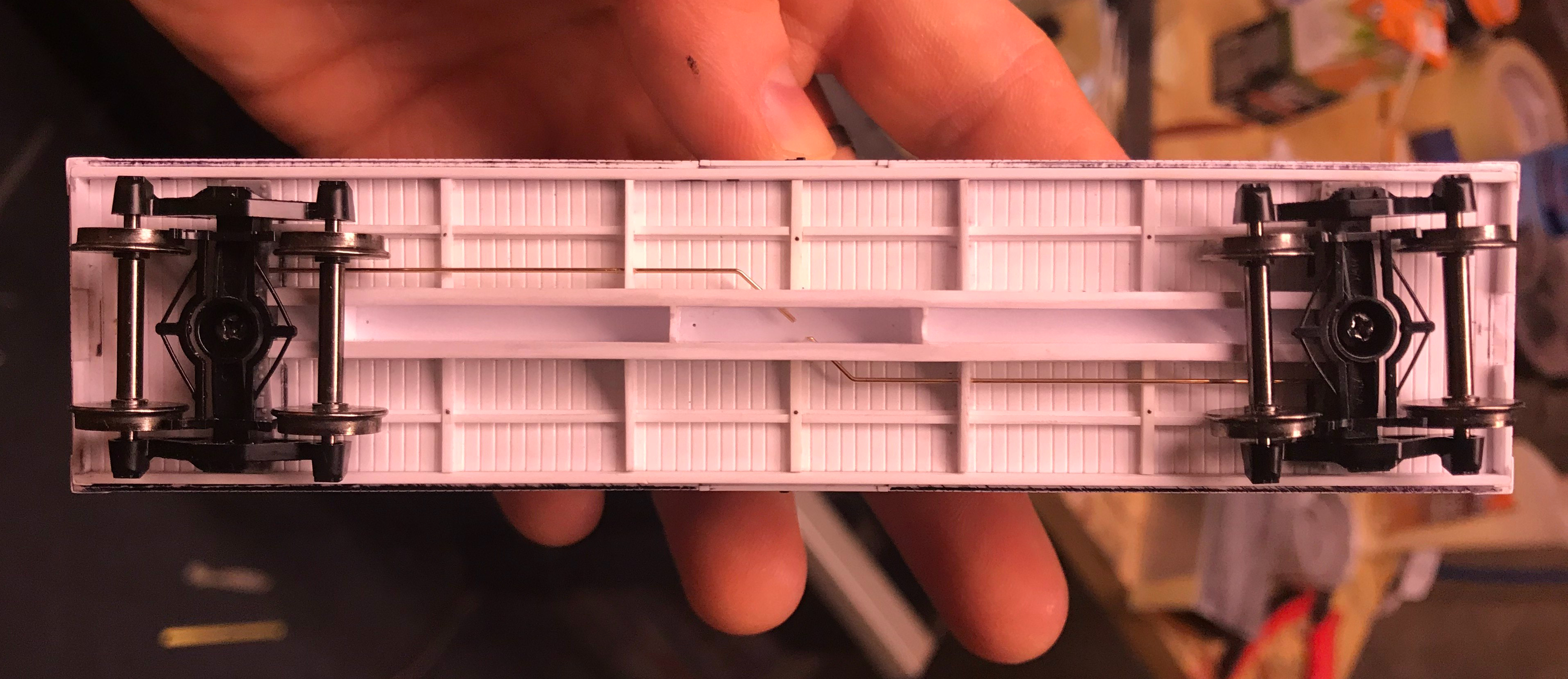

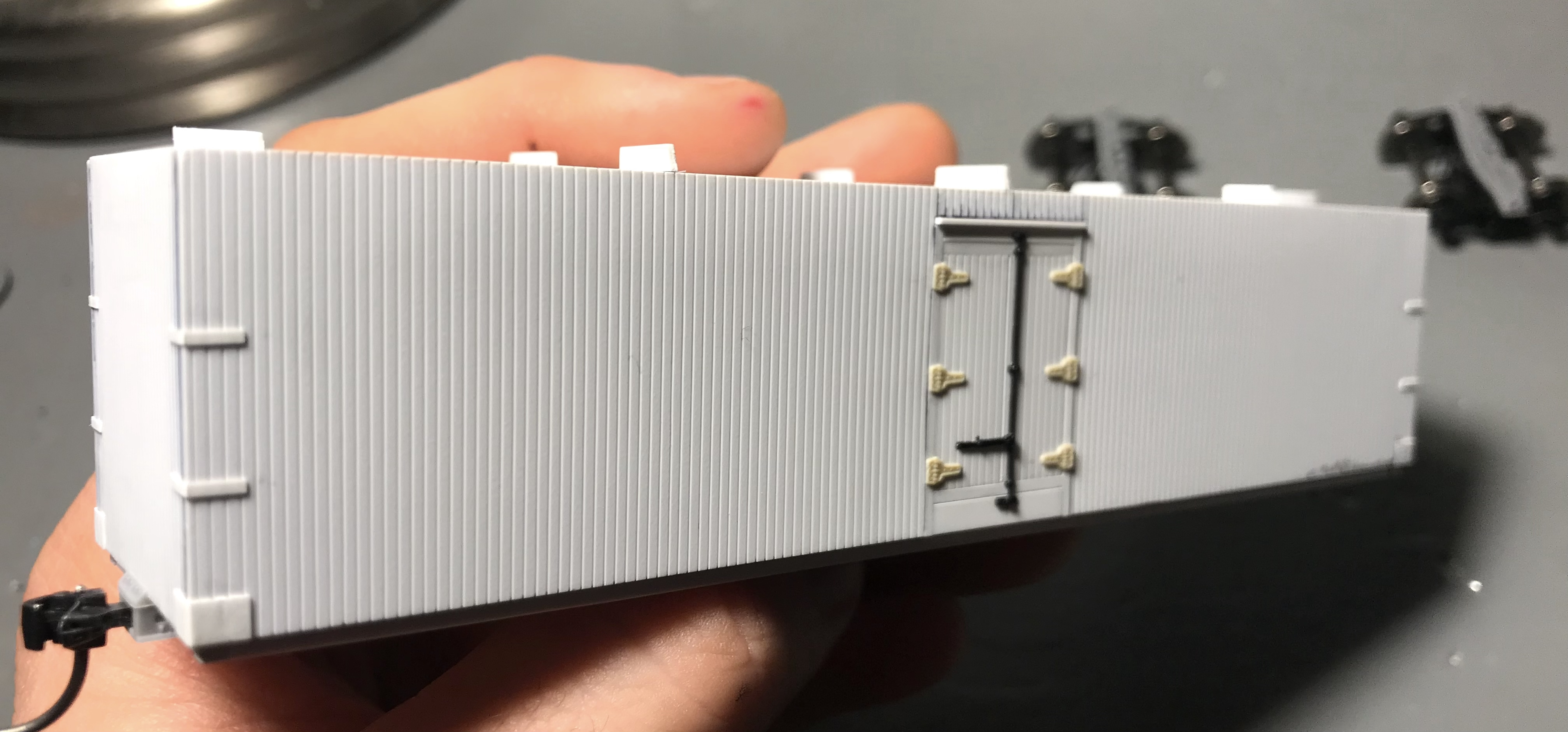

Last night, in the final hours of my 20s, I installed the underslung charcoal heaters and their piping onto Reefer cars’ underframe.

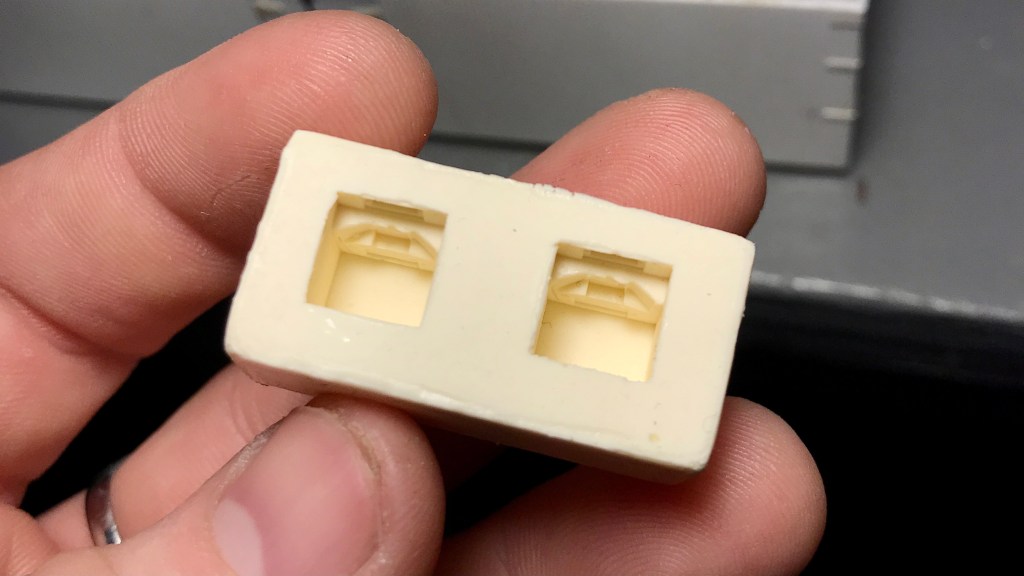

The heaters were resin copies I cast of a certain manufactures underslung charcoal heaters that I could not purchase individually from a kit. I cut a notch out of the previously installed Z-bracing and then affixed the heater right to the car floor with CA.

The piping was .032” Tichy PB Wire threaded through the car floor into small holes drilled into the heaters. I made the “T” joint by first filing the ends of the cut wire totally flat, then used masking tape to hold the wires together in the desired formation on top of some scrap wood. Flux was applied, and solder was liberally applied to the joint. I cleaned it up with 400 grit sandpaper, rubbing alcohol and a wire brush.

The bracing/strapping that holds the heaters to the car floor on the prototype will be installed after the final under-frame installation is made

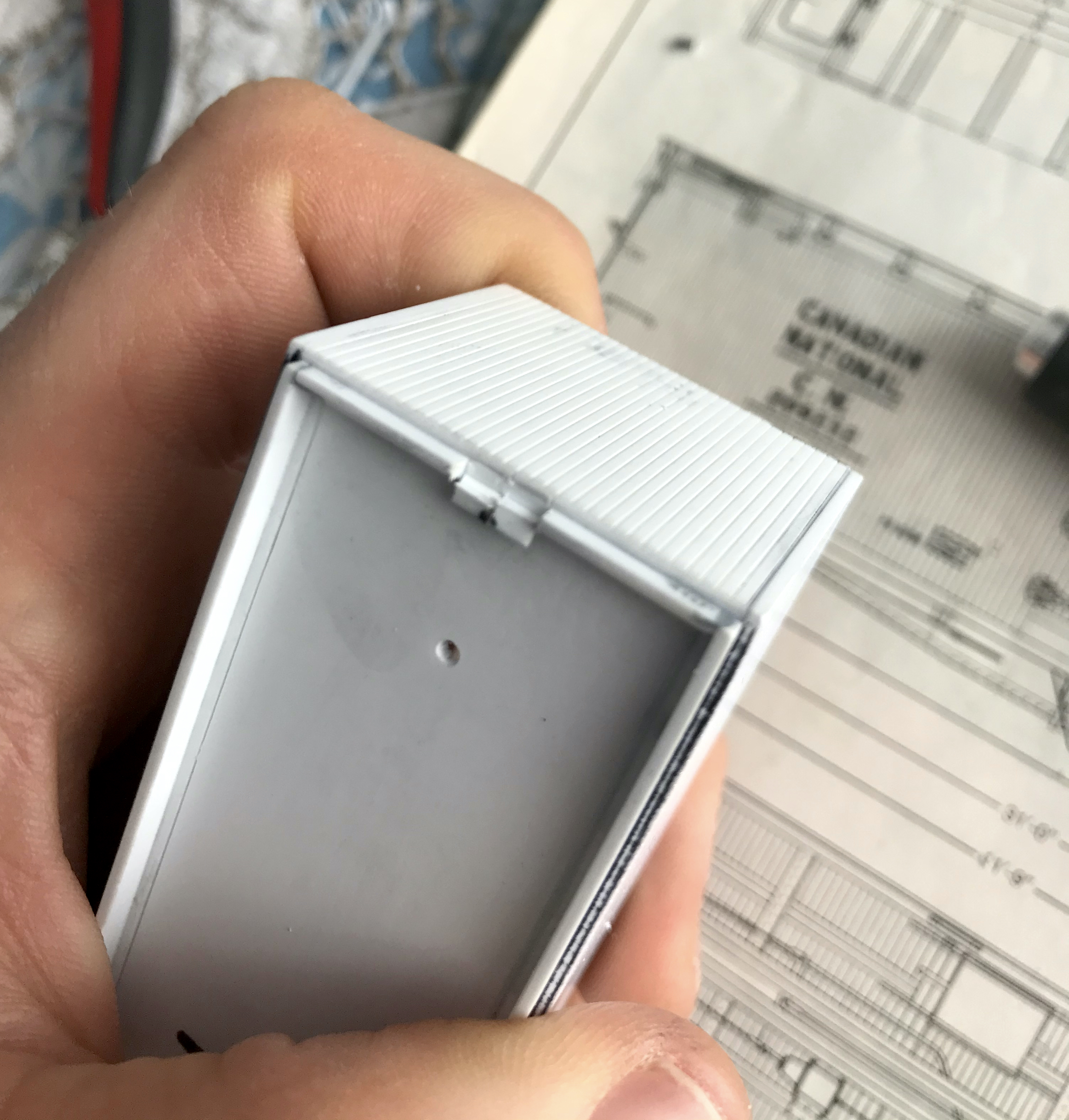

One of the first things I had to consider before taking on this project (almost a year ago !!!) was the availability of certain parts that would be rather difficult to scratch build- the big concerns being the roof hatches and the underslung heaters.

Well, I was able to find suitable hatches to use (Details West RH-1003). Still, underslung heaters were going to be a different story.

I tried emailing a certain resin kit manufacture multiple times to see if I could purchase some of their cast underslung heaters that they include in their Reefer kits but received no response.

Second, I took to Shapeways to see what I could find. I placed an order with a certain shop for some heaters that looked promising, but when I received them- though they were nice, they just didn’t look as nice as the other manufacturer’s part. And that just couldn’t do.

So, as a last resort, I raided a couple of unbuilt 8 Hatch Reefer kits I have in the closet, got a casting kit at Great Hobbies and cast my own resin copies of the underslung heaters; something I’d never done before.

I’ll spare the casting process, but I’m happy with how they turned out. And while it was a minor headache to not just buy the parts I wanted, this turned out to be a great learning experience, and I’ve learned a new skill.

[A note on ethics: I wouldn’t condone doing something like this (even for personal use only) if the parts in question were still in print and/or readily available. You should always support hobby shops and manufacturers whenever possible. Don’t be a dink.]